In photovoltaic (PV) system safety, rapid shutdown switches aren’t just regulatory checkboxes – they’re critical safety components, that protect first responders and maintenance personnel. Next, we will delve into the differences between module-level shutdown and string shutdown in detail.

What Are the Core Differences Between the Two Types of RSD?

In simple terms, the core difference between them is that component-level rapid shutdown can only control one solar panel, while string rapid shutdown can control a batch of solar panels.

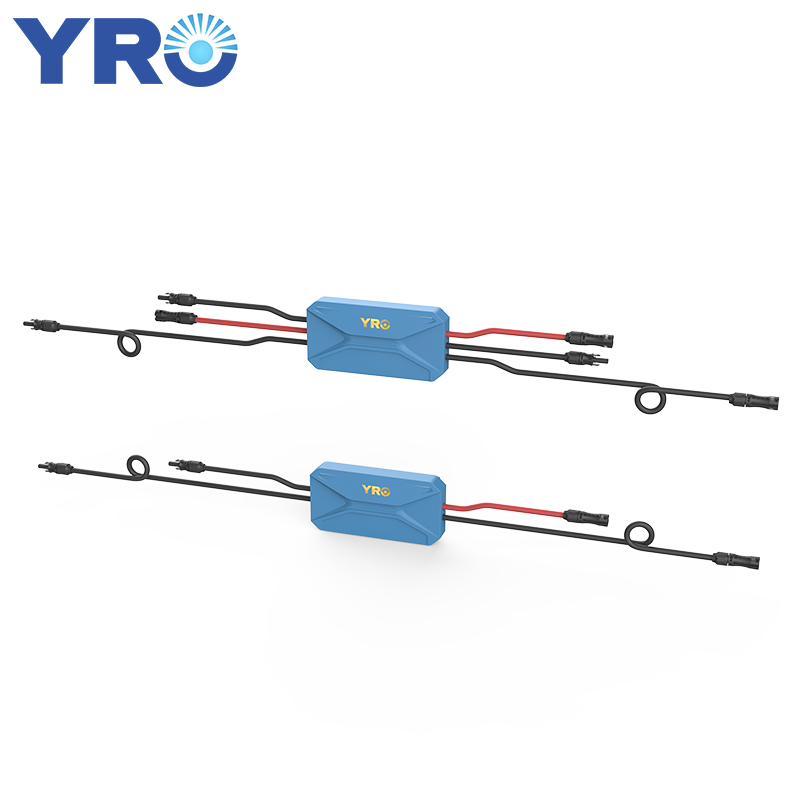

This classification method comprehensively considers cost-effectiveness, installation convenience, and the requirements of practical application scenarios. We have encountered situations like this: a customer had only 2 solar panels at home, but due to considerations for personal safety, property security, and compliance, they ultimately purchased a component-level shutdown device, which is internally referred to at YRO as the “small shutdown”. Compared to the string-level shutdown (large shutdown), the small shutdown has a lower price, making it more suitable for household users or application scenarios with fewer solar panels.

How Do the Two Shutdown Types Differ in Their Implementation Methods?

How Do the Two Shutdown Types Differ in Their Implementation Methods?

1、Hardware Structure

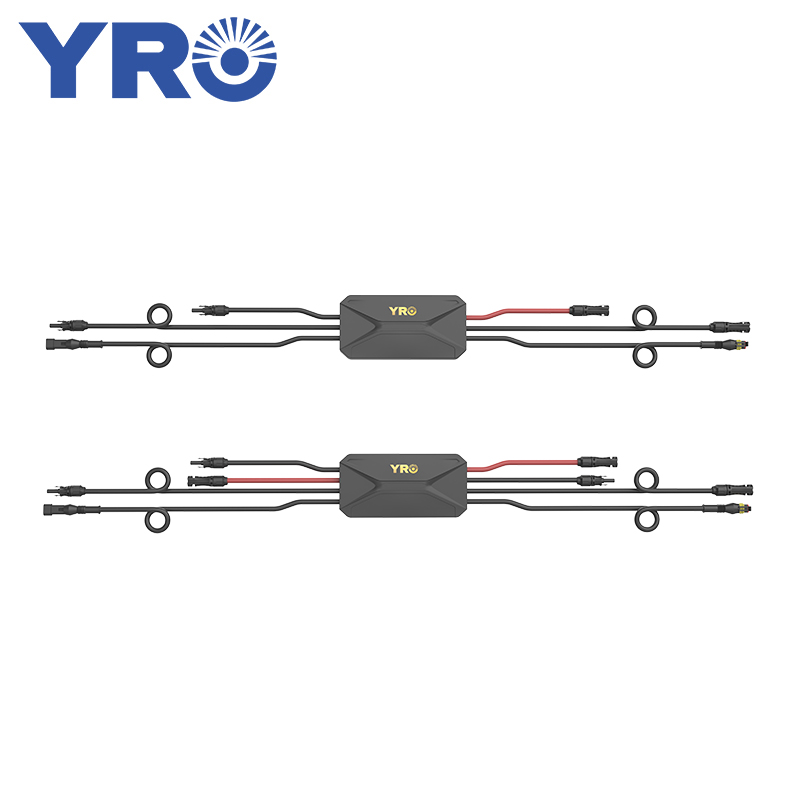

Large solar panel shutdown switch relies on relays or mechanical switches, with a simple structure. The small shutdown adopts electronic control (such as PLC communication and PLC protocol compatibility), and achieves rapid response through independent shut-off devices for each component.

2、Control Logic Differences

| Step | String-Level Shutdown | Module-Level Shutdown |

| 1. Trigger Signal | Controller sends encoded digital signals | Simple switch signal (24V DC on/off) |

| 2. Command Transmission | Broadcast via power line or wirelessly to all micro shutdown devices | Directly drives the relay coil |

| 3. Execution Action | Electronic switch cuts the current path on each module | Mechanical contacts separate, disconnecting the entire string circuit |

| 4. Voltage Decay | Active discharge of internal panel capacitance to <80V | Relies on natural discharge of the line |

3、Trigger Mechanism

The electronic switches of each component cut off the current path, and the mechanical contacts separated to disconnect the entire circuit.

YRO’s Rapid Shutdown Solutions

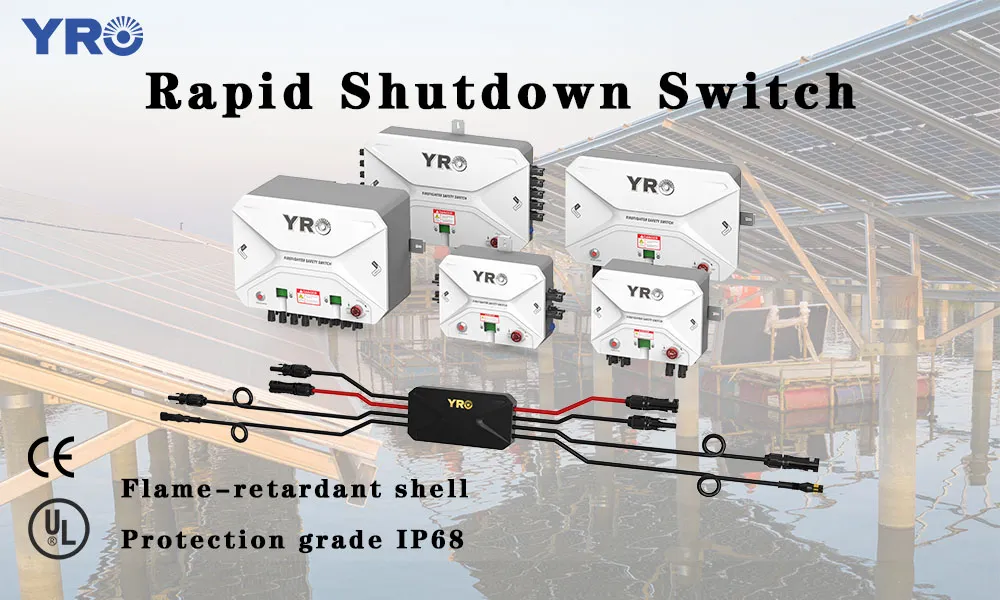

At YRO, we offer a full line of solar panel safety switches, that comply with international standards and are built for both string-level and module-level applications.

Why Choose YRO Rapid Shutdown Devices?

- Factory-Direct Production: As a manufacturer, we control every step—from mold design to final assembly—ensuring better quality and pricing.

- Certified Safety: Products come with CE and UL certifications, meeting global compliance requirements.

- IP68 Protection: Waterproof and dustproof, suitable for harsh outdoor conditions.

Choosing Between the Two: What Matters Most?

If your priority is simplified installation and cost-efficiency, a module-level shutdown is likely the better option. However, for projects with strict safety protocols or complex module layouts, string-level shutdowns are far superior in isolating hazards quickly and precisely.

Also, keep in mind the future scalability of your solar array. Systems that may expand over time or face changing safety regulations could benefit more from the flexibility and safety granularity of string-level solutions.

Conclusion

In summary, both rapid shutdown methods offer value, but your choice should be guided by installation scale, safety expectations, and long-term performance goals. YRO provides both options—reliable, certified, and ready for your solar energy project.

How Do the Two Shutdown Types Differ in Their Implementation Methods?

How Do the Two Shutdown Types Differ in Their Implementation Methods?