When planning a solar or electrical system, choosing the right combiner box is a decision that requires careful consideration. A good combiner box can improve safety, enhance system efficiency, and ensure the durability of the equipment in practical use. However, dealing with different configurations and technical requirements—such as current size, voltage matching, number of input circuits, protection level, etc.—may feel somewhat complicated. Below, we will explain step by step to help you make the right choice based on actual engineering needs.

1、Number of Circuits

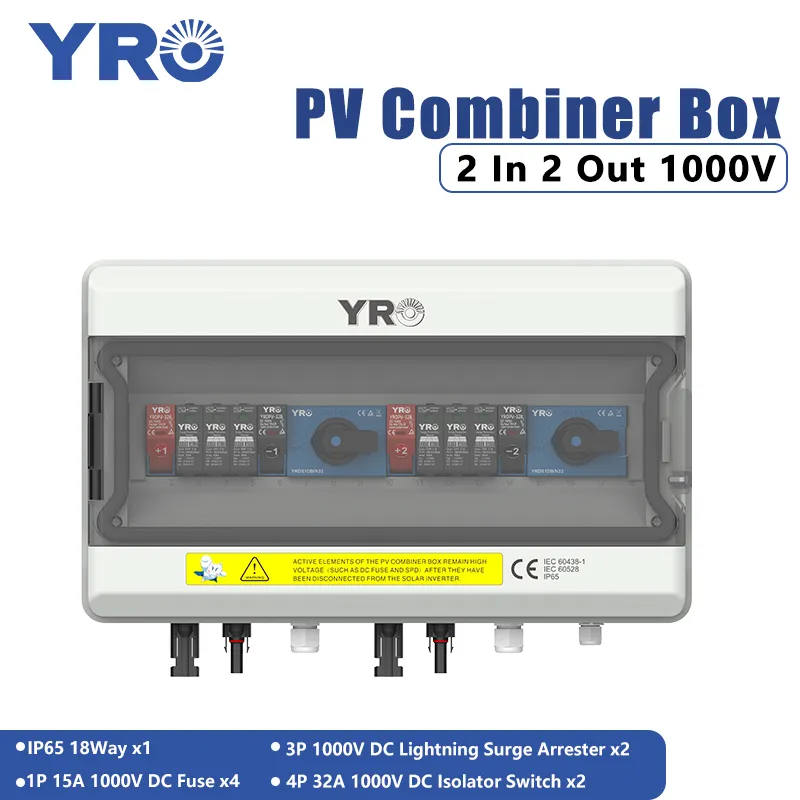

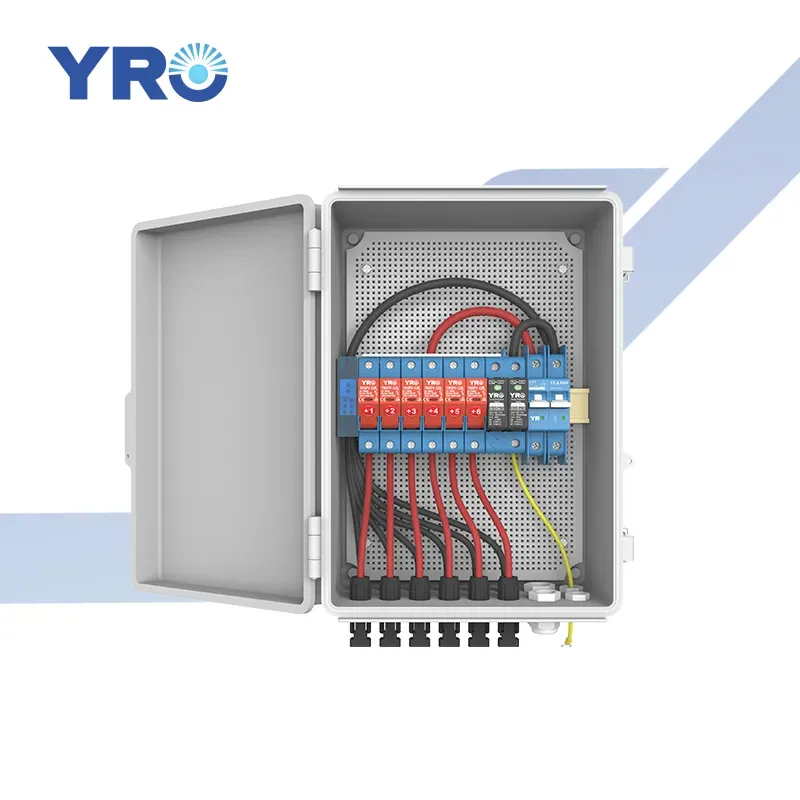

The number of input circuits, also known as the “number of strings,” determines how many PV strings the combiner box can connect. Common configurations range from 8 to 32 strings. Solar combiner boxes for residential systems typically require only 2 to 4 strings, while large commercial or power plant projects may need 16~32 strings or even more.

The number of strings not only affects the capacity of the combiner box, but is also related to the total current size. If the number of strings is large, it is necessary to ensure that the current carrying capacity of the DC combiner box is sufficient, and at the same time, the specifications of the fuses or circuit breakers should match it.

When choosing the number of input channels, we recommend taking into account both current needs and the possibility of future expansion. Choosing a configuration slightly more than the current demand, can leave room for adjustment in subsequent system upgrades and avoid replacing the entire combiner box later.

2、Current-Carrying Capacity

Each combiner box is designed to withstand a specific current. When solar panels or DC strings are connected, the total current may accumulate rapidly. If the capacity of the combiner box is insufficient, it is prone to overheating or electrical faults.

For instance, if a photovoltaic string outputs 10A of current and you connect six strings in parallel with a total current capacity of 100A, you should select a combiner box with a 100A current capacity.

How was 100A derived? Here is a formula: Imax=Nstrings*Isc*1.25

Nstrings: Number of photovoltaic strings;

Isc: Component short-circuit current (A);

1.25: Margin coefficient, the additional current margin reserved in design or calculation to deal with overload, uncertainty or safety redundancy (usually taken as 1.2 to 1.5).

Therefore, an ideal combiner box should incorporate fuses or circuit breakers that withstand such currents, and its rated current should preferably exceed the system’s maximum current to provide a safety margin for operation.

3、Voltage Matching

Different PV systems operate at different voltages—some at 600V DC, some at 1000V, and large power plants can reach 1500V. If the voltage rating of the combiner box does not match the system voltage, it can affect performance and safety.

A general rule of thumb is to choose a combiner box with a rated voltage, higher than the system’s maximum operating voltage. For example, if the system operates at 1000V, the distribution box should have a rated voltage of at least 1100V to withstand voltage fluctuations or instantaneous spikes.

4、IP Protection Rating

The PV output combiner box may be exposed to dust, rain and even bad weather. Therefore, the IP protection level is particularly important.

- IP20: Commonly used in indoor dry environments for distribution boxes, switches and sockets. It can prevent fingers from touching, but it is not waterproof.

- IP54: Dust and splash water. It is commonly found in indoor environments where water vapor may come into contact, such as kitchen appliances and factory equipment.

- IP65: Completely dust-proof and resistant to low-pressure water jets. This is a common and important standard for outdoor equipment such as solar distribution boxes, LED street lamps, and surveillance cameras.

- IP66: Completely dust-proof and resistant to strong water jets. It can be used in more demanding situations such as ship decks and car washing environments.

- IP67: Completely dust-proof and can be immersed in water for a short time (usually 1 meter deep, 30 minutes). It can be used for outdoor equipment that may occasionally be briefly submerged.

- IP68: Completely dust-proof and can work at a specified depth underwater for a long time. Used for underwater equipment, such as diving cameras and underwater sensors

The IP65 protection rating is already capable of meeting the requirements of most application scenarios. Even in the event of more severe environmental conditions, the IP66 rating can still provide sufficient protection.

5、Enclosure Material

The enclosure material affects the product’s durability. Plastic enclosures are lightweight and low-cost but perform less effectively against UV radiation compared to metal materials. Metal enclosures, such as painted steel or stainless steel, are generally sturdier but cost more than plastic enclosures.

If the installation environment has high temperatures, strong sunlight, or coastal conditions where corrosion may occur, we recommend choosing an enclosure made of stainless steel or UV-resistant polymer material.

6、Certification

6、Certification

Qualified distribution boxes should comply with international certifications such as CE, UL or IEC. This not only indicates reliable quality but also simplifies project acceptance. For EPC or installation companies, using certified equipment can reduce risks, facilitate insurance coverage and comply with local regulations.

7、Balancing Cost and Reliability

While cheaper options may seem cost-effective, they often lead to higher maintenance costs and shorter lifespans. Distribution boxes play a critical role in the safety protection of PV systems. Appropriately increasing the budget to choose more reliable products can result in longer stable operation times and reduced maintenance needs.

Conclusion

Choosing a suitable combiner box requires a comprehensive consideration of your specific environmental conditions, system design and operational requirements. Electrical parameters (voltage, current and the number of strings) should match the design of the photovoltaic array, and at the same time, the protection level also needs to meet the actual requirements of the installation environment.

Whether it is a family roof or a large-scale photovoltaic power station, taking the time to carefully evaluate these parameters will make the installation smoother, operation more reliable and maintenance more worry-free.