In modern energy systems, uninterrupted power supply has become a core demand in all industries. Hospitals, data centers, manufacturing plants and renewable energy facilities all rely on stable backup power systems to maintain smooth operation.

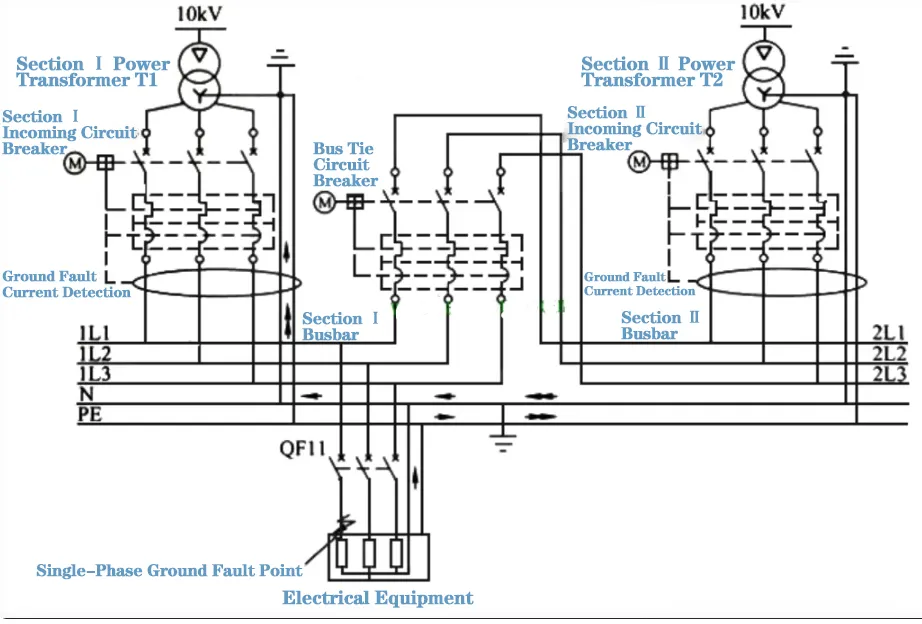

Most users who have encountered electrical systems understand the basic function of ATS, but few comprehend the complex evaluation process determining its two most critical performance metrics—conversion time and switching reliability. These two parameters form the backbone of ATS performance assessment. Conversion time determines how quickly systems can be restored online during a power outage, while switching reliability ensures this process occurs correctly every single time, regardless of circumstances.

Understand the ATS Conversion Time

Conversion time, often referred to as switching time, refers to the time required for the automatic transfer switch to switch the load to the backup power supply, after detecting that the main power supply is disconnected. This time is usually measured in milliseconds.

In power-sensitive environments like IT server rooms or medical facilities, even extremely short delays may cause power interruptions. Therefore, evaluating conversion time isn’t merely about numerical comparisons; it’s about ensuring users remain unaware of the power transfer process.

Evaluating the Switching Reliability

Conversion time measures speed, while switching reliability assesses consistency and accuracy. Switching reliability refers to whether the ATS can stably and repeatedly complete the switching when needed, without mechanical failure or inconsistent operation. Reliability testing typically includes: long-term performance testing, repeated switching cycles, durability verification, etc. Engineers will also monitor the wear of the contacts, to ensure that the ATS can withstand tens of thousands of operations throughout its entire service life.

Another factor influencing reliability is internal structural design. For example, electric power transfer switch units featuring upgraded materials, reinforced contacts, and advanced arc-extinguishing technology typically perform better under heavy loads. YRO’s ATS designs prioritize these considerations to ensure stability even after multiple switching operations.

Factors Affecting ATS Performance

- Load sensitivity: Critical applications demand minimal conversion time.

- Switching mechanism: Durability varies between mechanical and solid-state designs.

- Load capacity: High-current ATS must remain reliable under heavy loads.

- Environmental protection: CE certification and IP-rated enclosures ensure performance in harsh conditions.

- Manufacturer testing capabilities: Companies with in-house testing facilities (e.g., YRO) deliver more consistent quality.

From the Customer’s Perspective, What Should Be Focused On?

From the Customer’s Perspective, What Should Be Focused On?

For buyers, evaluating the conversion time and switching reliability of ATS can be rather complicated. Many technical parameters are not easy to understand. A practical approach is to consider it in combination with the application scenarios. For instance, hospitals might be more concerned with the shortest conversion time, while photovoltaic systems might focus more on long-term reliability.

In addition, customers should also pay attention to after-sales service and warranty. A reliable manufacturer of automatic transfer switches will provide technical support and corresponding product manuals, thereby ensuring the stable operation of ATS throughout its entire life cycle.

Summary

When choosing an automatic transfer switch, it is crucial to evaluate the transfer time and switching reliability. They determine whether power can be restored quickly and whether it can remain stable for a long time. By paying attention to test data, material quality, manufacturer experience and after-sales service, customers can make wiser choices.