Many rapid shutdown devices usually work properly right after installation. The real differences often become apparent only after the system has been running for several years.

During long-term use, the equipment undergoes multiple inspections, repeated switching, and is frequently operated in maintenance or emergency situations. Over time, internal wear and structural loosening may gradually emerge. This has led many users to question: Can the rapid shutdown device really be used reliably for a long time?

Challenges Faced by RSD in Indoor and Outdoor Environments

Depending on the system design, RSDs may be installed either in relatively enclosed indoor spaces or exposed to outdoor environments for extended periods. Both usage scenarios present different but equally stringent demands on the device’s stability and durability.

In indoor environments, although conditions are relatively stable, rapid shutdown devices still need to cope with the mechanical and operational stresses from long-term operation. For example, during system checks or maintenance, the device may need to be operated and switched multiple times. If the structural strength is insufficient, or the internal rotating parts lack sufficient wear resistance, operational stiffness and internal part loosening are likely to occur after prolonged use.

In outdoor environments, the challenges faced by the safety shutdown switch are more direct. It needs to endure prolonged exposure to intense sunlight, extreme cold, rain, snow, and strong winds. In this case, the robustness of the structure directly affects whether the device can maintain reliability over the long term. If the product lacks sufficient strength, repeated thermal expansion/contraction or external stress will accelerate its aging.

Why Do Many Problems Appear Only After Several Years?

Many users find it difficult to notice the differences between products when they initially select them because:

- The initial structure was already complete

- Internal components have not yet accumulated wear

- The number of operations is not yet frequent

However, as time goes by, repeated switching, maintenance disassembly, and long-term operation will gradually magnify the design differences. If the internal key components are not wear-resistant, or the structure was not designed with long-term mechanical stability in mind, then problems often tend to surface in concentrated form after several years.

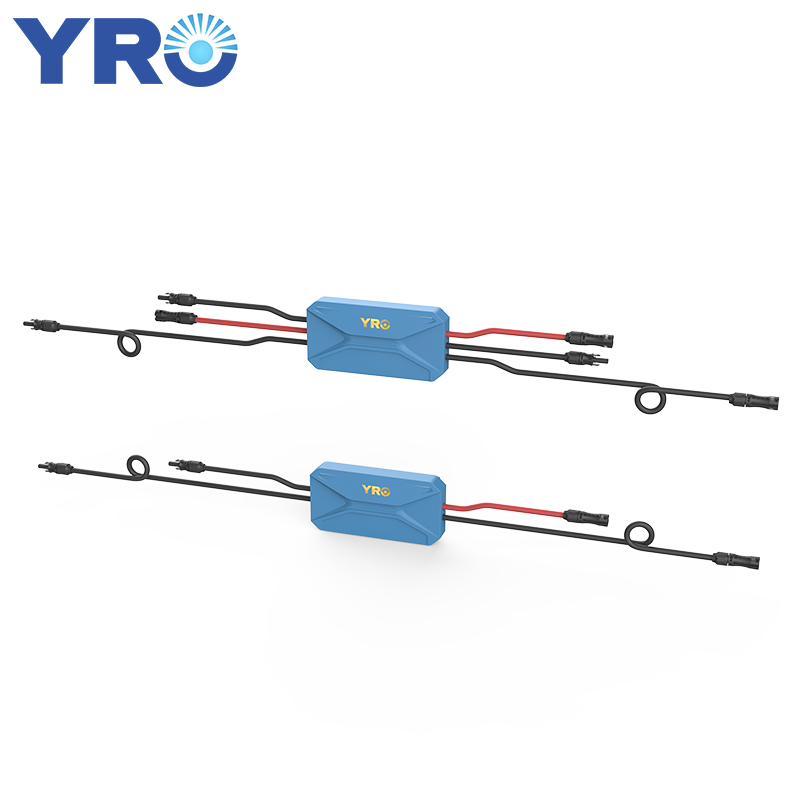

YRO Launches the Second-Generation Solar Rapid Shutdown Switch

The design goal of the second-generation rapid shutdown is very clear—to target long-term stable use, with specific optimizations to the structure and key internal parts.

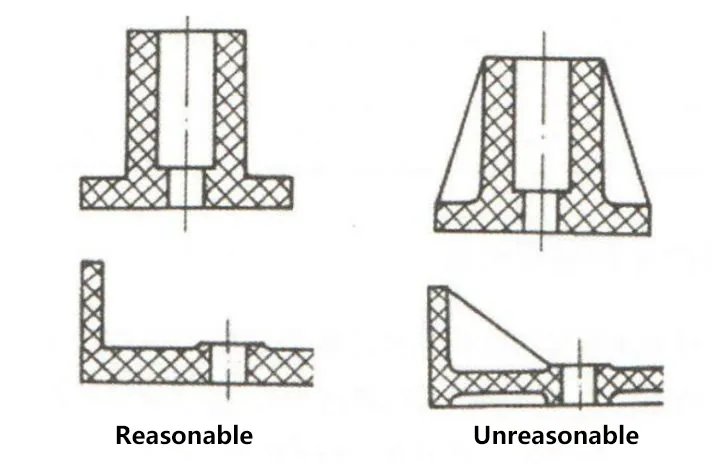

Structure is More Robust

During the upgrade process, additional strengthening ribs were added to the screw columns, which will strengthen the face cover and make the overall structure more stable. Such improvements can effectively reduce the risk of loosening caused by repeated assembly and disassembly, prevent the sealing of the shell from being damaged, and prevent moisture and dust from entering, which can lead to circuit corrosion and premature failure.

Key Internal Components are More Durable

We know that each activation of the RSD switch causes wear. Initially, the wear might be minimal, but after 100, 200, or more mechanical wear cycles, it can gradually affect internal performance.

The upgraded solar rapid shutdown changed the switch material to aluminum alloy. The advantages of aluminum alloy are that it is lightweight, corrosion-resistant, and more wear-resistant than plastic. Even after hundreds or thousands of rotations, the switch is less prone to causing jams.

What Practical Changes Will the Second-Generation Solar Panel Emergency Switch Bring?

- Cost reduction: Although the initial cost of high-quality RSD may be slightly higher, it eliminates the expense of expensive maintenance services.

- Longer service life: The upgraded components are more durable and can withstand multiple opening and closing operations as well as long-term use, resulting in less mechanical wear and tear. Compared to the ordinary version, it is less likely to experience loosening or jamming due to repeated operations, and has a longer overall service life.

- More complete equipment: Ordinary plastic screw columns may develop tiny cracks after experiencing temperature changes and wind over a long period, affecting the sealing of the shell. The upgraded version adds reinforcing ribs, enabling the shell to maintain good integrity and sealing for many years, reducing the risk of internal moisture or dust entry due to structural problems.

Conclusion

Whether the emergency rapid shutdown can last for many years, depends on whether it can withstand the test of time and usage scenarios.

The upgraded shutdown switch provides a more reliable foundation for long-term use through structural reinforcement and optimization of key components. For users who value the long-term stability of the system, such an upgrade is of practical significance.