In vielen Elektroinstallationen, Stromkreisunterbrecher sind in der Regel in Reihe mit der Last geschaltet und nicht nur auf der Stromversorgungsseite installiert. Sie werden sich vielleicht fragen: Warum eine solche Konstruktion? Ist eine solche Konfiguration wirklich notwendig? Dieser Artikel befasst sich mit den Gründen und Vorteilen der Reihenschaltung von Leistungsschaltern mit Lasten.

Hauptgrund: Schutz des Stromkreises

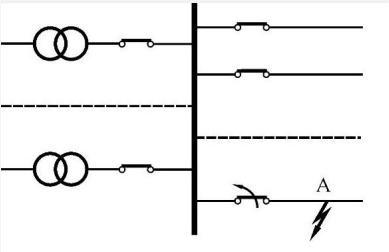

Die Hauptfunktion eines Stromkreisunterbrecher ist es, Überlast- oder Kurzschlussstrom zu erkennen und abzuschalten. Nur wenn der Strom vollständig durch den Schutzschalter fließt, kann er den Stromkreis bei einem Fehler sofort ausschalten und verhindern, dass der Strom weiter zur Last und zu den vorgeschalteten Geräten fließt. Wenn der Schutzschalter parallel zur Last geschaltet ist, teilt sich der Strom auf, und ein Teil des Stroms kann vom Schutzschalter nicht erfasst werden, was dazu führen kann, dass die Schutzfunktion nicht normal funktioniert.

Stromnetze mit Kurzschlussfehlern

Vorteile der Reihenschaltung von Leistungsschaltern

Bildung eines einzigartigen Strompfads zur Erzielung einer "Serienauslösung"

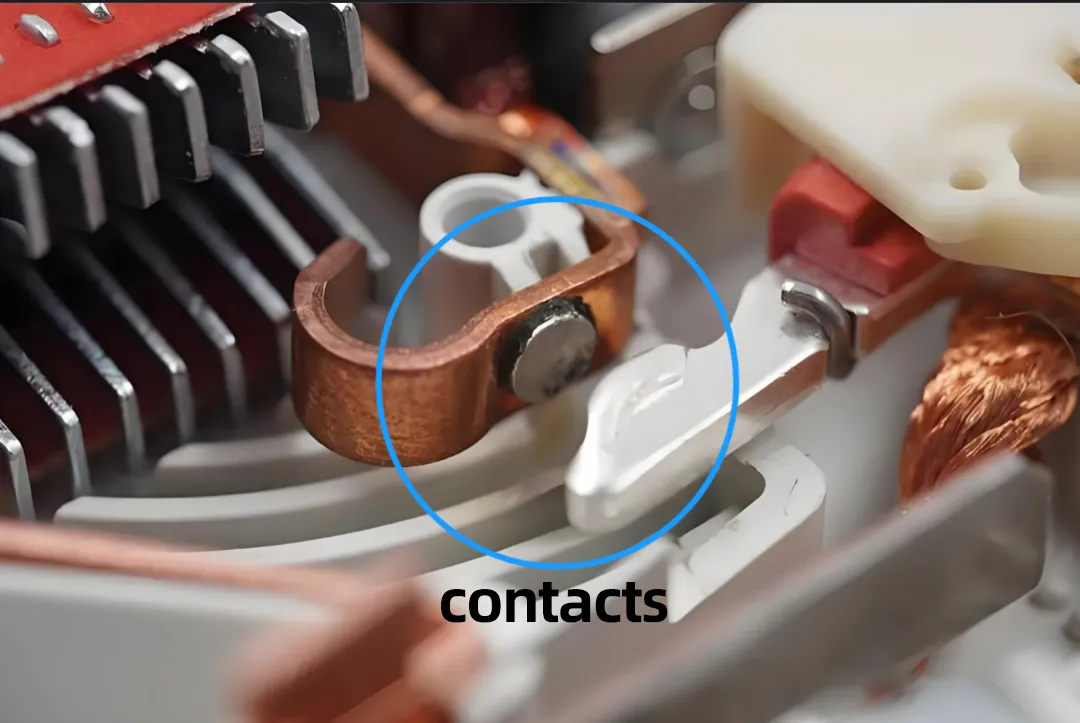

Bei herkömmlichen Schutzschaltern sind die Kontakte, die Strommesselemente und die Lasten im selben Stromkreis in Reihe geschaltet. Wenn der Schutzschalter auslöst, wird daher der gesamte Stromkreis sofort unterbrochen und alle nachfolgenden Lasten werden abgeschaltet. Diese Einwegfunktion macht die Fehlersuche und Systemwiederherstellung übersichtlicher und zuverlässiger.

Selektiver Schutz für den gesamten Stromkreis

In Stromverteilungssystemen wird häufig zuerst ein Hauptleistungsschalter in der Hauptleitung und dann Abzweigleistungsschalter in den Abzweigleitungen installiert. Die Reihenschaltung zwischen dem Hauptleistungsschalter und den Abzweigleistungsschaltern ermöglicht es dem vorgeschalteten Leistungsschalter, bei einem schweren Fehler in einem Abzweig zuerst zu reagieren und so zu verhindern, dass sich der Fehlerstrom auf das gesamte Verteilungsnetz ausbreitet, wodurch ein hierarchischer und selektiver Schutz erreicht wird.

Erleichterung der Koordinierung mit anderen Schutzkomponenten

Wenn das Ausschaltvermögen eines Leistungsschalters nicht ausreicht, werden häufig Sicherungen oder andere strombegrenzende Komponenten in Reihe vor und hinter den Schalter geschaltet, um einen "Doppelschutz" zu bilden. Diese Reihenschaltung kann bei verschiedenen Fehlern getrennt funktionieren und erhöht die Zuverlässigkeit des Gesamtsystems.

Verschleißerkennung und Wartung von Leistungsschaltern nach langfristigem Betrieb

Warum sollte man auf den Verschleiß von Leistungsschaltern achten?

Bei langfristiger Nutzung, selbst unter normalen Betriebsbedingungen, verschleißen die internen Schlüsselkomponenten eines Leistungsschalters allmählich. Dies kann dazu führen:

- Verlängerte Auslösezeit

- Geringere Genauigkeit des Schutzes

- Erhöhtes Risiko eines Totalausfalls

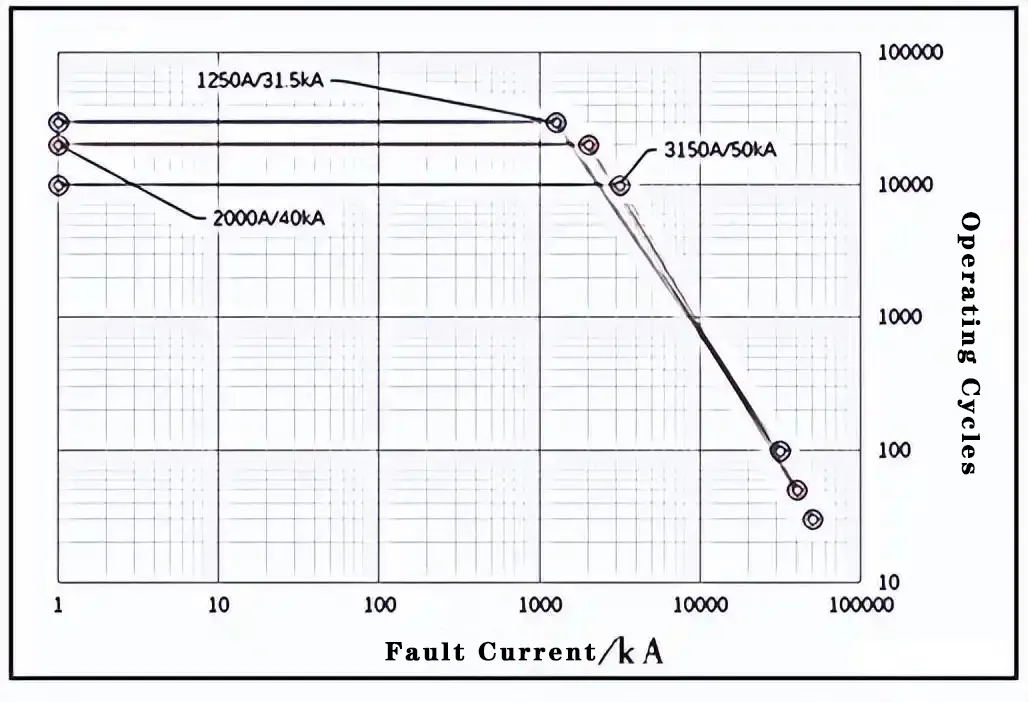

Theoretische elektrische Lebenskurve von Vakuum-Leistungsschaltern

Überblick über die wichtigsten Verschleißteile

| Komponente | Hauptverschleißmechanismus | Entdeckung Signifikanz |

| Bewegliche und feststehende Kontakte (Lichtbogenkontakte) | Lichtbogenkorrosion, mechanische Einwirkungen, die eine Ausdünnung der Kontaktfläche verursachen | Bestimmt direkt das Ausschaltvermögen und die Lebensdauer des Leistungsschalters |

| Betätigungsmechanismus (Feder, Gestänge, Puffer) | Mechanische Ermüdung, Schlagverschleiß | Beeinflusst Aktionszeit und Zuverlässigkeit |

| Lichtbogen-Löschkammer / Lichtbogen-Löschmittel (Vakuum, SF₆, Öl) | Kumulative Lichtbogenenergie, mittlere Alterung | Bestimmt die Lichtbogenlöschwirkung und den Isolationsgrad |

| Isolier- und Dichtungselemente (Gummi, Fett) | Thermische Alterung, chemische Zersetzung | Beeinflusst die Isolationsstärke und die Leckageprävention |

| Erfassungs-/Steuerungsschaltung (Stromwandler, Relais) | Spulenalterung, schlechter Kontakt | Beeinflusst die Empfindlichkeit der Schutzfunktion |

Nachweismethoden und praktische Empfehlungen

Kontakt Erkennung

- Verwenden Sie eine Infrarot-Wärmebildkamera oder ein spezielles Strommessgerät, um festzustellen, ob der Temperaturanstieg der Kontakte abnormal ist.

- Achten Sie darauf, ob sich auf der Oberfläche der Kontaktstellen Abriebspuren, Verkohlungen oder schlechter Kontakt befinden.

Betätigungsmechanismus und Feder

- Prüfen Sie manuell oder mit Hilfe von Prüfgeräten, die den Vorgang simulieren, ob der Schließ- und Öffnungsvorgang reibungslos verläuft und ob die Federkraft nachgelassen hat.

- Testen Sie die Pausenzeit und die Erholungszeit, um sicherzustellen, dass sie innerhalb des Standardbereichs liegen.

Lichtbogen-Löschgerät

- Achten Sie darauf, ob in der Lichtbogenlöschkammer oder in der leitenden Rohrleitung offensichtliche Kohlenstoffablagerungen oder Schäden vorhanden sind.

- Reinigen oder ersetzen Sie regelmäßig Verschleißteile, um die Zuverlässigkeit des Leistungsschalters zu gewährleisten.

Umfassende Wartungsempfehlungen

Für Leistungsschalter kritischer Lasten kann ein Plan für die regelmäßige Inspektion erstellt werden, der die tatsächliche Betriebszeit und die Anzahl der Auslösungen berücksichtigt.

Bestimmen Sie anhand der Erkennungsdaten, ob ein Austausch oder eine Reparatur erforderlich ist, um unerwartete Stromausfälle oder Geräteschäden zu vermeiden.

Schlussfolgerung

Die Stromkreisunterbrecher muss mit der Last in Reihe geschaltet werden, was eine Grundvoraussetzung für die Gewährleistung des normalen Betriebs des elektrischen Sicherheitsschutzsystems ist. Mit zunehmender Nutzungsdauer müssen wir auch auf den Verschleiß der internen Komponenten des Leistungsschalters achten. Durch regelmäßige Inspektion und Wartung können wir sicherstellen, dass er in gutem Betriebszustand bleibt.

Die richtige Anschlusstechnik und regelmäßige Zustandsüberprüfungen sind wichtige Maßnahmen zur Aufrechterhaltung der elektrischen Sicherheit.