Yes, you heard it right. Just recently, we received news from the R&D line that YRO’s new generation of Stromkreisunterbrecher has quietly completed its upgrade and is about to be officially unveiled.

We believe many old friends, like us, have a question in mind: In such a mature market, what new tricks can a circuit breaker possibly pull off?

Today, I’ll take you through what exactly has been upgraded in the new circuit breaker. What are the differences compared to the old model? In this article, we’ll take a clear look at each point, one by one.

What Has YRO Upgraded?

Appearance Upgrade

Appearance Upgrade

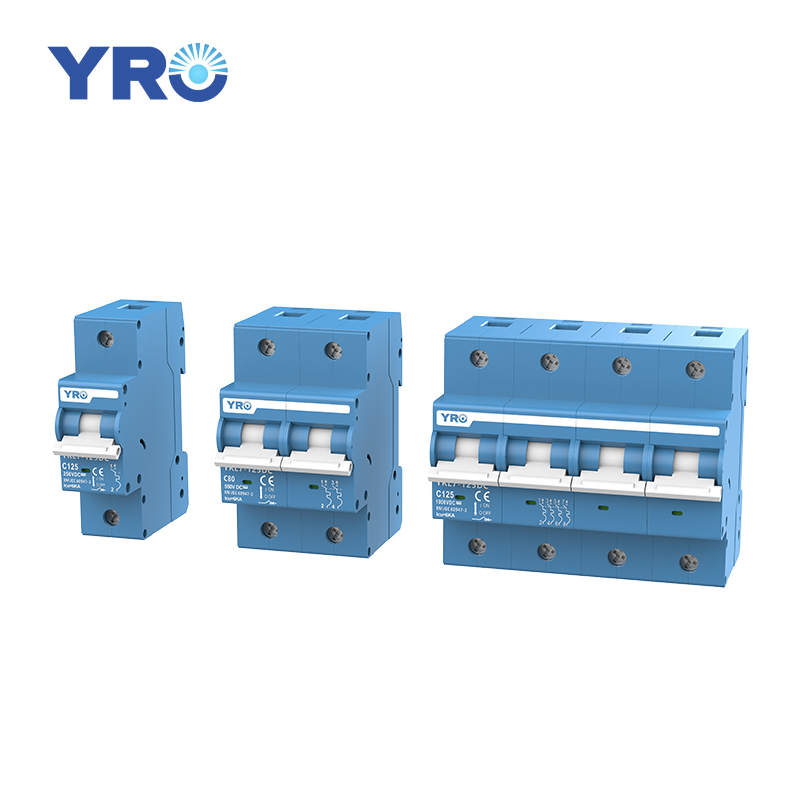

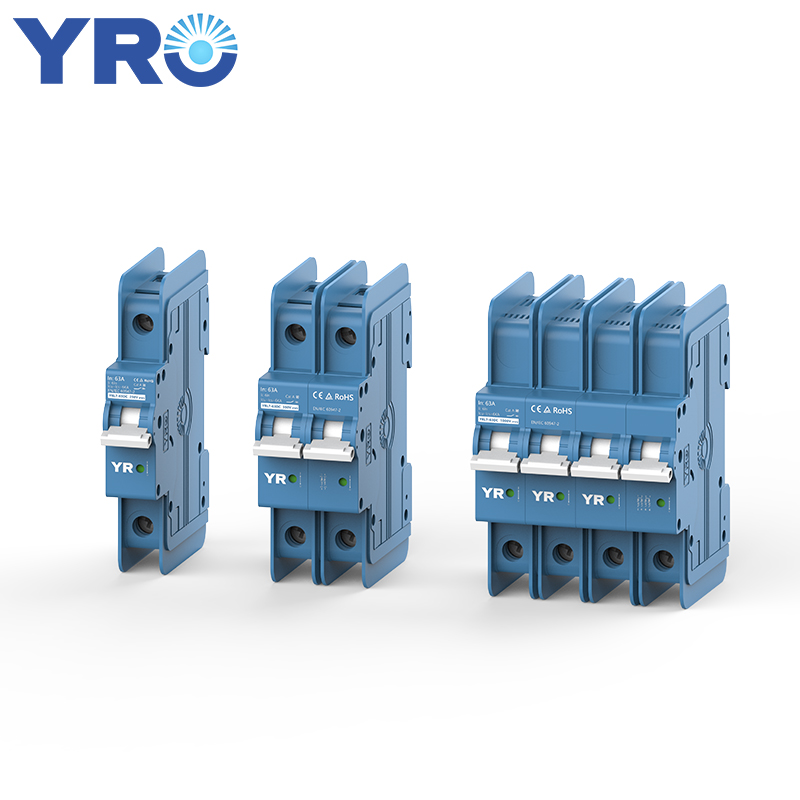

The most immediate change comes from the appearance. The new YRO circuit breaker features a completely redesigned outer shell structure, boasting an independent exterior design protected by patents.

The clearer structural outline and more rational shape layout make the circuit breaker easier to identify within a distribution box or cabinet, helping to reduce misjudgments during installation and maintenance.

For comparison:

- The old model’s appearance was quite conventional, similar to many products on the market.

- The new model features an independent design, making it easier to distinguish in densely installed environments.

Safety Enhancement

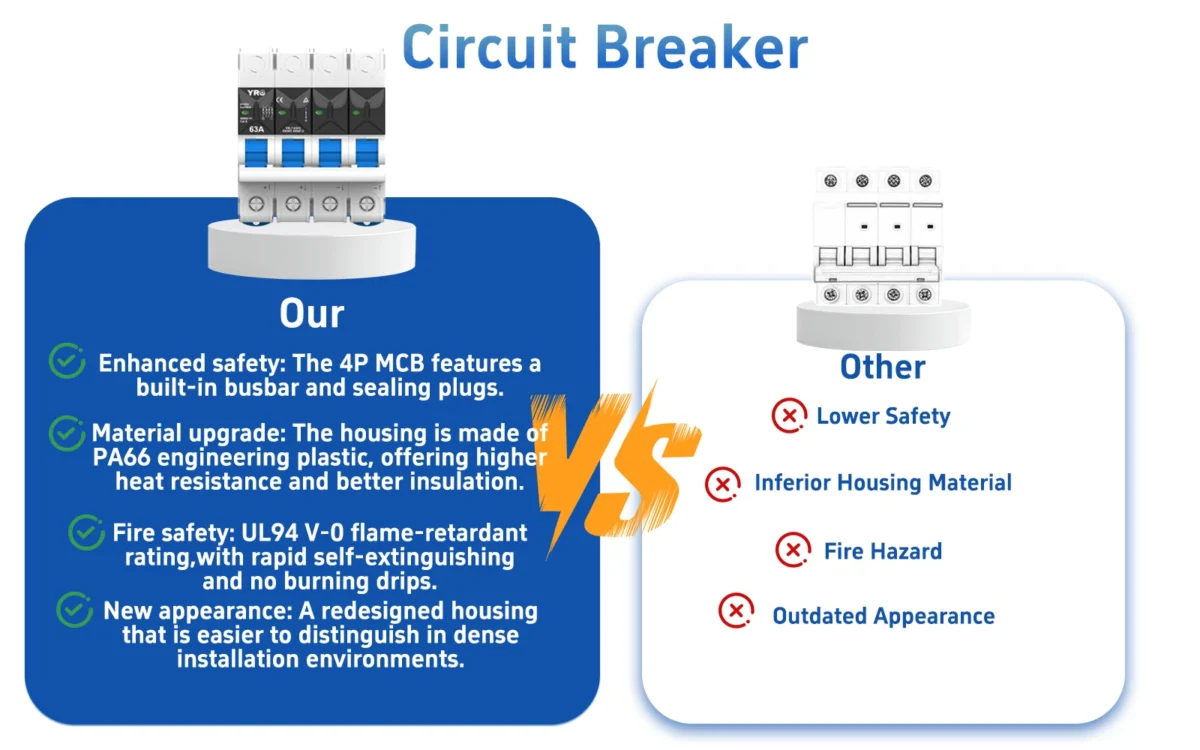

In der new 4P circuit breaker, YRO has carried out targeted optimization to the internal structure, upgrading it to an integrated busbar and adding a sealing plug structure.

The integrated busbar ensures a more reliable connection; the sealing plug acts as a physical barrier, preventing dust from entering. This effectively reduces potential hazards from unnecessary contact and makes the internal layout more controlled and safer.

For installers, the operation is clearer; for users, the system operation is more reassuring.

Material Optimization

Material is a key factor determining the long-term stability of a circuit breaker. The new YRO circuit breaker features an upgrade in its outer shell material to PA66.

PA66 refers to Polyamide 66, also known as Nylon 66, a type of high-performance engineering plastic.

Why Use PA66 for a Circuit Breaker Shell?

Die miniature circuit breaker is an electrical device, and the shell material needs to meet the following demanding conditions, and PA66 is exactly capable of fulfilling them:

- Heat resistance (HDT approximately 250°C): The circuit breaker generates arcs and heat during operation, and PA66 can maintain strength at high temperatures and is less likely to deform.

- Mechanical strength (impact resistance): It has high tensile strength and impact strength, protecting the internal precise switch mechanism from external collisions and damage.

- Insulation performance: The electrical insulation performance of PA66 is excellent, effectively preventing current leakage.

Fire Safety

In electrical safety, flame retardancy is not just a feature – it is a necessity. Our new circuit breaker now carries a UL94 V-0 rating.

UL 94 is a plastic flammability standard developed by Underwriters Laboratories in the United States. It evaluates a plastic’s reaction to an open flame, measuring ignition time, self-extinguishing properties, and whether burning drips can ignite a cotton indicator. UL 94 is compatible with other international standards, making it globally applicable for flame retardant safety testing.

V-0 is the most stringent tier within its classification (among V-0 / V-1 / V-2). To achieve the V-0 rating, the following strict conditions must be met:

- Short Self-Extinguishing Time

During two flame application tests, the flame exposure time must not exceed 10 seconds, and the material must self-extinguish within 10 seconds after the flame is removed each time.

- No Burning Drips

The material must not drip any flaming molten material during combustion. This is critical because falling hot melt can ignite other objects below, leading to fire spread.

During normal use, the material’s flame-retardant properties are hard to perceive directly. However, in the event of an accident, it plays a practical role in controlling risk. This improvement reflects consideration for product safety details, going beyond merely meeting basic standard requirements.

Updates Closer to Real Installation Scenarios

In actual applications such as distribution boxes and distribution cabinets, the installation space is limited and the construction period is tight. Any detail design may affect operational efficiency and safety.

In this miniature circuit breaker upgrade by YRO, instead of pursuing overly complex structures or functions, it focused on continuously optimizing the structure, safety and materials based on real application scenarios, making the product more suitable for the current electrical system requirements.

Schlussfolgerung

From the old model of DC circuit breaker to the new one, there are four key updates – appearance, enhanced 4P safety features, PA66 shell material, and UL94 V-0 flame retardant grade – all addressing the actual needs of users of electrical protection equipment.

The old model circuit breaker already had reliable performance, and the new product further improved its performance on this basis. It not only meets the basic requirements but also provides further protection.

For users who are evaluating whether to update their circuit breakers, the new YRO circuit breaker offers a more reliable, secure, and practical choice.

Appearance Upgrade

Appearance Upgrade