Exploring the Essentials of Knife Type Fuses

In the intricate world of electrical circuits, the role of a fuse is pivotal for ensuring safety and reliability. Among the various types of fuses, the knife type fuse stands out for its unique design and specific applications. This article delves into the mechanics, uses, and significance of knife type fuses in electrical systems.

Understanding Knife Type Fuses

Understanding Knife Type Fuses

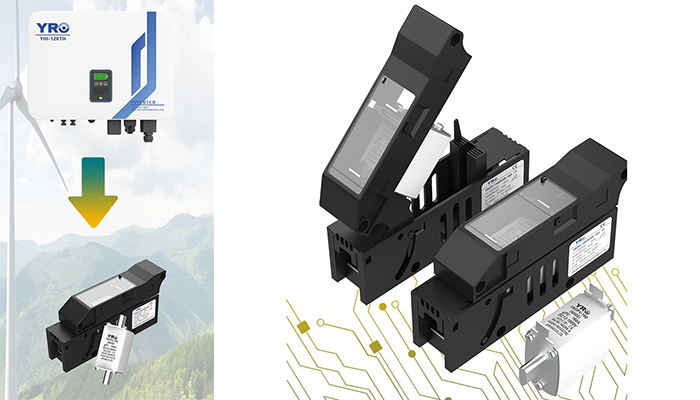

A knife type fuse is a kind of fuse wherein the fuse element is connected to the circuit through blade-like contacts. This design allows for easy insertion and removal from a fuse holder, resembling the action of a knife being sheathed and unsheathed.

Key Characteristics:

- Design: Comprises a fuse element enclosed within a cartridge, with knife-like blades protruding from both ends.

- Material: Typically made of a fusible metal wire or strip that melts when excessive current flows through it.

- Contact Points: Blade contacts ensure a secure and stable connection within the fuse holder.

Working Principle

The fundamental working principle of a knife type fuse revolves around the concept of overcurrent protection. When current flowing through the fuse exceeds a predetermined threshold, the heat generated by the electrical resistance of the fuse element causes it to melt (or ‘blow’), thereby interrupting the circuit and preventing potential damage.

Applications and Uses

Knife type fuses are extensively used in various applications, particularly where high current ratings and robustness are required. Common areas of application include:

- Industrial Settings: Used in control panels, motor circuits, and industrial machinery.

- Power Distribution: Employed in distribution boards and power transformers for overcurrent protection.

- Renewable Energy Systems: Integral in solar panels and wind turbine circuits for safeguarding against current surges.

Advantages of Knife Type Fuses

- Ease of Replacement: The knife-like design allows for easy insertion and removal without the need for specialized tools.

- High Interruption Capacity: Capable of handling high current and voltage, making them suitable for industrial applications.

- Reliability: Provides a simple yet effective way to protect circuits from overcurrent conditions.

- Visual Indication: Often designed to offer a visual indication of fuse status, aiding in quick maintenance and troubleshooting.

Safety Considerations

While knife type fuses offer reliable protection, it’s crucial to adhere to safety protocols during installation and replacement:

- Correct Rating: Always use a fuse with the appropriate current and voltage rating for the circuit.

- Power Off: Ensure that the power is turned off before replacing a fuse to avoid electric shock.

- Inspection: Regularly inspect fuse conditions and replace them if any signs of wear or damage are evident.

Knife type fuses play a critical role in electrical safety, offering efficient and reliable overcurrent protection in various high-demand applications. Their simple design, ease of use, and robust performance make them an indispensable component in the realm of electrical circuit protection. As technology evolves, these fuses continue to be integral in safeguarding complex electrical systems, thus underscoring their enduring significance in the electrical industry.

For professionals and businesses operating in environments where electrical safety and reliability are paramount, understanding and effectively utilizing knife type fuses is not just a matter of compliance, but a proactive step towards ensuring uninterrupted operations and safeguarding assets.

Understanding Knife Type Fuses

Understanding Knife Type Fuses