An UV aging test, also known as a UV weathering test or UV exposure test, is a laboratory test conducted to evaluate the effects of ultraviolet (UV) radiation on materials, products, or samples over a specified period of time. The purpose of this test is to simulate the long-term exposure to UV radiation that materials and products may experience when exposed to sunlight and other sources of UV radiation in outdoor environments.

UV radiation from the sun can cause various forms of degradation and deterioration in materials and products, including:

- Color Fading: UV radiation can lead to the fading of colors in materials such as textiles, paints, plastics, and coatings.

- Material Degradation: Exposure to UV radiation can break down the molecular structure of materials, leading to cracking, embrittlement, and reduced mechanical strength.

- Surface Chalking: Some materials can develop a powdery or chalky surface when exposed to UV radiation.

- Yellowing: Plastics and other materials can yellow or become discolored when exposed to UV radiation.

- Loss of Transparency: Transparent materials like glass and plastics can become cloudy or lose their transparency over time.

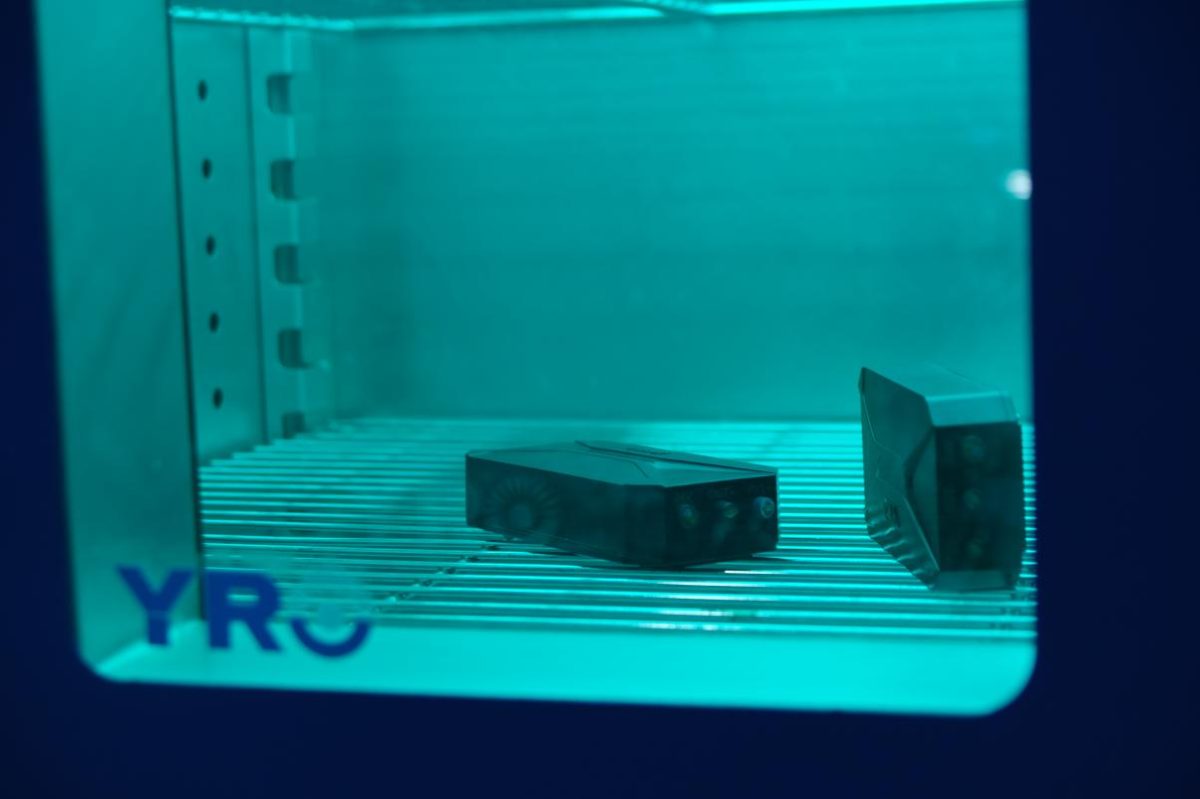

UV aging tests involve subjecting test samples to controlled levels of UV radiation, typically using specialized UV lamps or chambers that emit UV light in a controlled manner. The samples are exposed to UV radiation for a specified number of hours or days, depending on the test requirements. The conditions, including UV intensity and temperature, are carefully controlled to simulate real-world conditions as accurately as possible.

After the exposure period, the samples are evaluated for any changes or degradation that occurred due to UV exposure. This evaluation may include measurements of color change, changes in material properties, and visual inspection for surface damage.

UV aging tests are commonly used in industries such as automotive, aerospace, construction, textiles, and plastics to assess the durability and performance of materials and products when exposed to UV radiation. The results of these tests can help manufacturers make informed decisions about material selection, product design, and the expected lifespan of their products in outdoor or UV-exposed environments.

Benefits of UV Aging Testing

- Material Durability Assessment: UV aging tests help assess how materials and products will perform when exposed to prolonged UV radiation. This is particularly important for outdoor applications, as it allows manufacturers to select materials that can withstand environmental conditions and maintain their integrity over time.

- Quality Control: Manufacturers can use UV aging testing as a quality control tool to ensure that their products meet durability and performance standards. By subjecting samples to accelerated UV aging, they can identify potential issues and make design or material adjustments before products reach the market.

- Product Development: UV aging testing is valuable during the product development phase. It helps engineers and designers select the most suitable materials and make design improvements to enhance a product’s resistance to UV-induced degradation. This can lead to the creation of longer-lasting and more reliable products.

- Cost Savings: Identifying material or design weaknesses early in the development process can lead to cost savings by preventing expensive recalls, warranty claims, and product failures in the field. It allows companies to invest in materials and designs that provide better long-term performance.

- Regulatory Compliance: Some industries, such as automotive and aerospace, have strict regulations and standards regarding the performance and durability of materials and components exposed to UV radiation. UV aging testing can help ensure compliance with these regulations.

- Predictive Maintenance: In sectors like infrastructure and construction, UV aging testing can be used to predict maintenance needs for outdoor structures and materials, helping to plan for necessary repairs or replacements before significant deterioration occurs.

- Consumer Confidence: Demonstrating that a product has undergone rigorous UV aging testing and can withstand UV exposure can instill confidence in consumers. It can also serve as a marketing advantage, especially for outdoor and UV-exposed products.

- Research and Development: Researchers can use UV aging testing to study the degradation mechanisms of materials under UV radiation, leading to a deeper understanding of material behavior and potential innovations in material science.

- Long-Term Warranty Validation: Manufacturers can use UV aging testing to validate long-term warranties on products, as they can demonstrate that their products have been tested under conditions that replicate real-world UV exposure.

- Environmental Impact Assessment: UV aging testing can help assess the environmental impact of materials and products, as it simulates the effects of prolonged exposure to sunlight and UV radiation, which can contribute to the degradation of materials and release of harmful substances.

In summary, UV aging testing is a valuable tool for evaluating the durability, performance, and reliability of materials and products exposed to UV radiation. It contributes to improved product quality, longevity, and overall customer satisfaction while helping manufacturers meet industry standards and regulations.