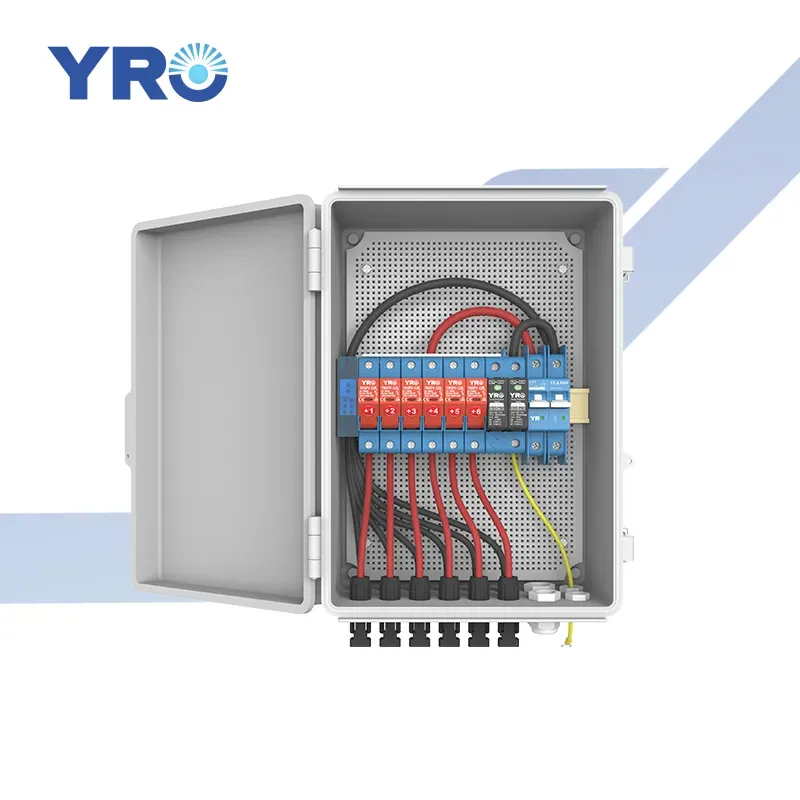

During the installation of photovoltaic systems, the correct installation of combiner boxes is a key link to ensure the efficient and safe operation of the system. As a device for connecting multiple sets of photovoltaic modules, the combiner box plays a crucial role in aggregating and uniformly outputting electrical energy. Although its working principle is relatively simple, if it is not installed in a standardized manner, it will not only lead to a decrease in the system’s power generation efficiency and an increase in maintenance costs, but also may pose serious safety hazards. This article provides a detailed introduction to the core steps and precautions for the installation of solar combiner boxes.

1、Pre-installation Planning

Inspect the combiner box’s packaging and enclosure for any damage, and ensure the product certificate, accessories (such as terminals and screws), and user manual are complete.

Open the box and verify that the combiner box’s model, protection rating, and component specifications meet the design requirements. Check that the enclosure is free from deformation or scratches, the door opens and closes properly, and internal components are intact with secure wiring.

If defects are found, take photos for documentation and contact the supplier immediately. Installation should proceed only after the product has been rectified and approved.

2、Site Assessment and Location Selection

Determine the optimal position of the combiner box through a comprehensive on-site assessment. The ideal combiner box should be installed at:

- Apply the position close to the photovoltaic modules to reduce the cable length and voltage drop

- Place it in a well-ventilated and shaded area to avoid overheating

- It should be vertically fixed on a flat surface such as a wall or a bracket

- Even if the combiner box has a protection level of IP65 or above, it should be avoided from being directly exposed to rain as much as possible

In addition, it is recommended to use waterproof connectors and UV-resistant cables to enhance the reliability of outdoor installations.

3、Wiring

Electrical connections must be performed with the combiner box de-energized and in accordance with the manufacturer’s wiring diagram. The diagram should include:

- The number of input strings and output circuits

- Recommended wire gauges for DC and grounding cables

- Standard torque values for each terminal

Improper wiring can not only affect power output, but may also cause overloading or damage to components such as fuses, circuit breakers, or surge protection modules.

4、Grounding

Grounding is an important step that cannot be ignored. Correct grounding not only prevents electrical faults but also effectively deals with voltage surges caused by lightning strikes.

Firmly connect the grounding wire to the combiner box and the grounding system. If in a high-humidity or coastal environment, be sure to check whether the connection points are rusty or loose.

5、Organize and Fix the Cables

All input and output cables should be neatly routed and secured using cable ties or conduits. Loose cables are not only unsightly but also prone to wear due to vibration, UV degradation, or rodent damage.

6、Testing

Before capping and sealing, please be sure to complete a series of basic tests:

- Conduct a connectivity test to verify whether the circuit connection is correct

- Check the insulation resistance (≥2MΩ)

- Confirm that the polarity of all circuits is correct

- Verify grounding through grounding resistance test

- Check for loose connections or foreign objects

Where conditions permit, the test results can be recorded on file as the basis for future maintenance or warranty

Summary of Precautions

- Use insulated tools and wear personal protective equipment

- Be sure to cut off the power supply before starting the wiring or testing

- Clearly mark the input and output lines to facilitate later maintenance

- Do not exceed the rated voltage and current range of the combiner box

If the product contains a lightning protection module, the status of the module should be checked regularly and replaced in a timely manner if necessary.

Final Checklist

Before sealing the enclosure, confirm the following:

- Are all input strings clearly labeled?

- Are all terminal connections properly tightened?

- Is the enclosure correctly sealed for waterproofing?

- Is the grounding reliable?

- Have voltage and insulation resistance tests been passed?

Conclusion

Although the installation of photovoltaic combiner boxes accounts for a relatively small proportion in the entire solar energy system, its significance cannot be ignored. Correct installation not only enhances the overall system efficiency but also significantly reduces operational risks and maintenance frequency.

When installing photovoltaic combiner boxes, it is essential to refer to local electrical standards and manufacturer instructions.