In the field of industrial power distribution and low-voltage power systems, the truly valuable progress often does not stem from disruptive changes.

Rather, product improvements often come from some less obvious but gradually valuable details that are optimized over the long term.

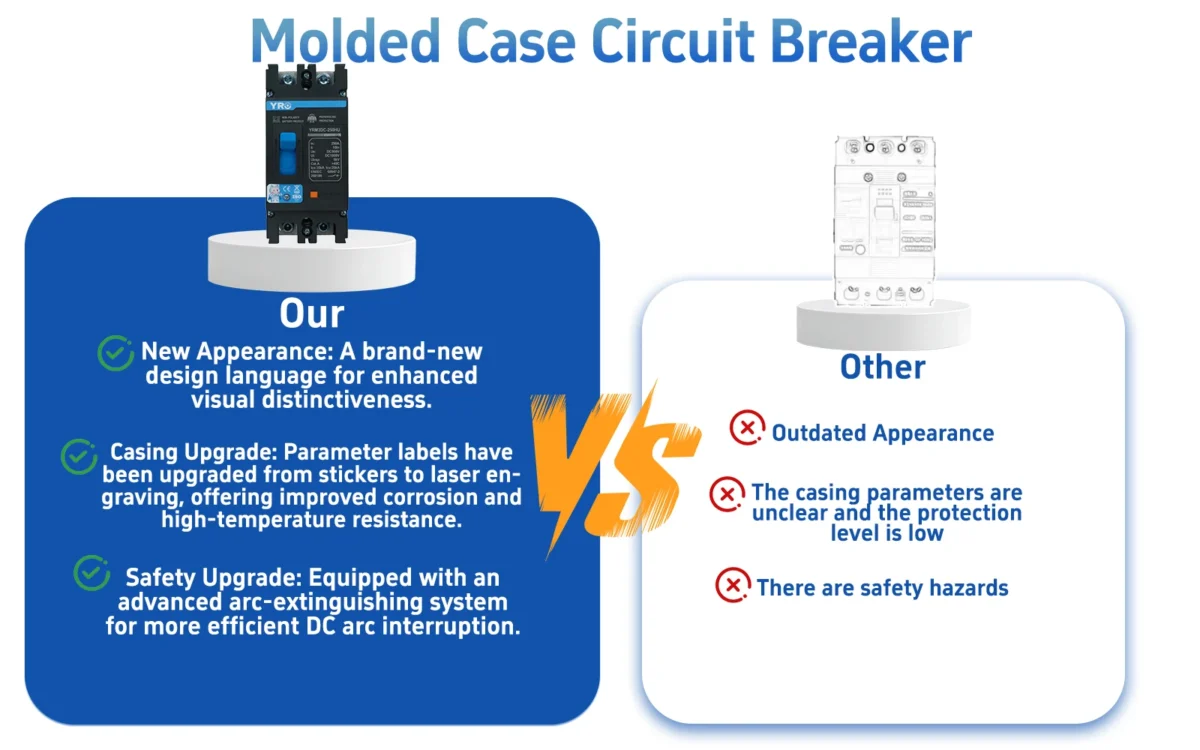

This time, the updates made by YRO to the molded-case circuit breaker are based on this mindset.

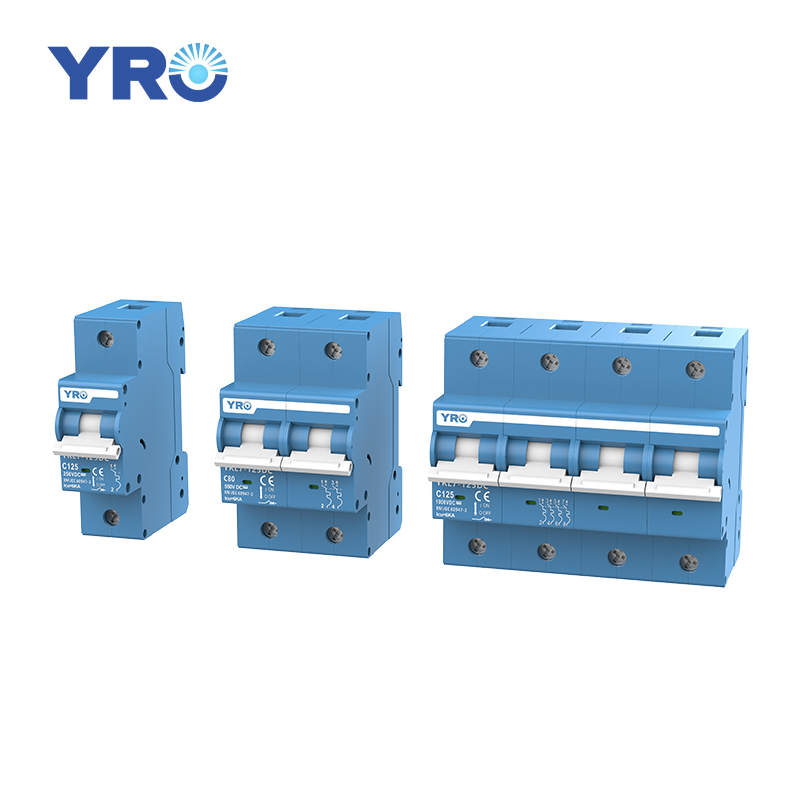

Upgrade One: Enhanced Aesthetic Design

In crowded electrical cabinets or industrial facilities, quick identification can save valuable time during maintenance or emergencies. That is why we improved the MCCB’s appearance to make it more visually distinctive.

The upgraded aesthetic design is more unified in proportion, lines, and level of detail, making the circuit breaker easier to identify in actual cabinet environments.

From a manufacturing perspective, such adjustments also help improve the consistency of mass production.

Upgrade Two: Laser-Engraved Parameter Labels

Parameter labels are often overlooked in many electrical products.

Traditional printed markings are prone to fading or falling off over time due to temperature, humidity, dust, and cleaning operations.

In this upgrade, all key parameter labels have adopted laser engraving technology. The resolution of laser printing (usually between 600-2400 DPI) can ensure the sharpness of the text and graphics, and the printed parameters rarely have ink smudging or blurring problems.

In addition, the carbon powder fixed by laser printing has water-resistant and wear-resistant properties, ensuring that the product packaging will not easily fade during transportation and use.

Upgrade Three: New Arc Chute

Among all upgrades, the one with the highest technical content, but least visible to the naked eye is the optimization of the arc chute structure.

Under normal operating conditions, it is almost unnoticeable. However, during breaking actions, the design and stability of the arc chute directly affect the overall performance of the circuit breaker.

During fault interruption, the guidance and dispersion of the arc are primarily handled by the arc chute.

Whether the arc chute structure is reasonable not only relates to the controllability of the breaking process, but also affects the stress and aging of internal components over long-term use.

This upgrade re-optimizes the internal structure and layout of the arc chute, enabling the arc to be more effectively guided and dispersed during the breaking process, which helps reduce the impact of localized heat concentration.

Conclusão

O latest plastic housing circuit breakers from YRO are not just incremental adjustments – they demonstrate our dedication to details. From enhancing the appearance to improve on-site recognition, to laser-engraved labels to ensure long-term clarity, and to the redesigned arc chute to improve arc extinguishing performance, every change is designed with the end user in mind.

These improvements are not separate design adjustments but rather gradually formed based on long-term manufacturing experience and actual usage observations.

As a manufacturer with independent production capabilities, YRO can clearly understand how design details affect assembly efficiency, quality stability, and long-term reliability.

These improvements collectively enhance reliability, simplify maintenance, and enable your installation to cope with changing challenges and have future adaptability.